Quality begins with the material.

Brake discs and brake drums are made out of unmachined castings containing flake graphite (grey cast iron). The configuration of the cast iron is based on the one of the vehicle manufacturer for brake discs. Different ingredients are added on the basic material, in order to influence positively the properties of cast iron for durability and machining. Supplements in the iron alloy like e.g. copper, molybdenum, titanium and carbon are analyzed in the OE discs and are also used for the Zimmermann discs. Therefore cast material for each individual brake disc of Zimmermann matches with the OE parts.

Over the last few years, an increasing number of brake discs, which are not identical to the respective original part in terms of their design and function, have been sold on the market. Tests have revealed, that basic material specifications in particular, but also changes to tolerances result in deformations and increased cracking of brake discs.

Otto Zimmermann GmbH has been performing inertia dynamometer tests and driving tests together with TÜV NORD Mobilität GmbH & Co. KG on an ongoing basis for more than 10 years, at great financial cost. On the basis of these tests, we are able to offer the free spare parts market qualitatively equivalent spare parts.

Zimmermann brake discs are "spare parts of the same quality" as original brake discs. The third-country brake discs tested by TÜV NORD do not fulfill this demand.

In all the brake discs tested, third-country products break considerably more quickly. The Zimmermann brake disc and the original product therefore have a significantly longer life expectancy.

The thermo-mechanical deformation is identical for the Zimmermann brake disc and the original brake disc. The third-country brake disc falls significantly below this level with respect to nearly all the criteria tested.

- Made in Germany in conformity with DIN EN ISO 9001:2008 and

DIN ISO TS 16949 - Consistently high product quality meeting the very highest quality standards

- Responsible awareness of your safety

- Reliability

- In-house development

- Permanent program maintenance and extension

-

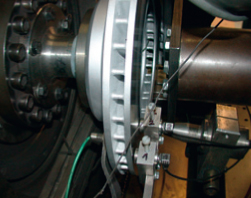

Zimmermann Brake Disc with 200 brake applications in the overload test

-

Competitors brake disc with 81 brake applications in the overload test