Brake discs play a crucial role in safety and performance of a vehicle. This is why workshops should use high-quality spare parts for repair work in order to bring more safety to the road and guarantee the satisfaction of their customers. Brake expert Otto Zimmermann GmbH uses extensive quality assurance measures to ensure the highest safety standards for their manufactured spare parts. At all stages of production permanent checks were executed by using state-of-the-art testing equipment, even own brake test benches are available.

Outstanding spare parts quality for satisfied customers

Otto Zimmermann brake discs undergo extensive testing to ensure optimum braking performance, heat resistance and durability of the materials. However, the brake disc alone does not ensure excellent braking performance - the perfect interaction of brake pad and brake disc is crucial. For this reason, Otto Zimmermann's brake pad compounds are matched during the development stage in such a way that the greatest possible intersection of safety, braking comfort and economy is achieved and the pad not only fits the brake disc perfectly but also the entire brake system.

"Quality starts with the material," says Otto Zimmermann, "but you don't always recognize it at first glance."

Many brake discs from different manufacturers on the spare parts market do not appear to be any different on the outside.This is why the experts at Otto Zimmermann provide workshop operators with detailed information so that they can better assess the quality of spare parts. The company is committed to sensitizing workshops to the quality of spare parts and supporting them in achieving greater customer satisfaction. "With our products, we not only rely on advanced technologies, but also on the trust of garages. Quality, safety and reliability are our top priorities when it comes to supplying workshops with spare parts in original part quality," emphasize the managers at Otto Zimmermann.

The highest standards in production make the difference

Otto Zimmermann brake discs offer the on a par quality as original brake discs, as the manufacturer uses a cast material quality comparable to that of the vehicle manufacturer.

The gray cast iron used offers high compressive strength, excellent damping and low wear properties as well as good thermal conductivity. The high compressive strength of the material is due to the evenly distributed carbon lamellae in the gray cast iron (see illustration on the left), which form three-dimensional ramifications and thus ensure high stability. If oxygen is trapped during the casting process, oxidation occurs on the graphite lamellae (see illustration on the right) when the disc heats up while braking. As a result, the thermal conductivity of the cast material suffers, the brake disc is not heated evenly and therefore cannot cool down evenly. According to Zimmermann, it is therefore important to work exclusively with foundries that carry out the casting and cooling process perfectly and can meet the individual casting specifications of the respective brake disc.

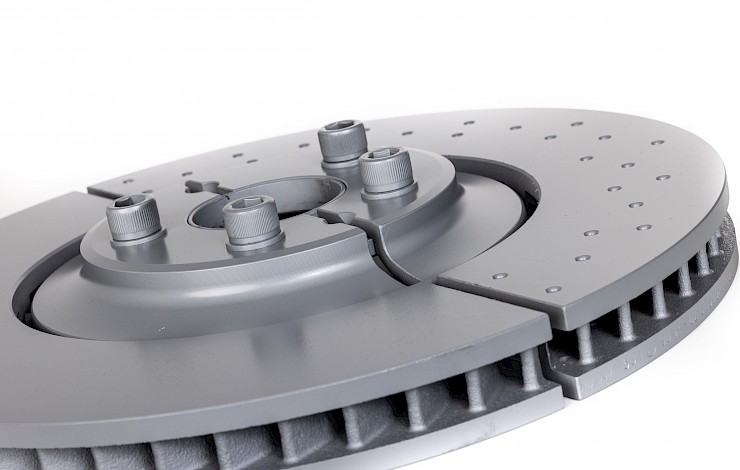

A closer look at the width of the ventilation channels also provides information about the quality of the brake discs. If you look at the dimensions and design, the ventilation ducts manufactured by Otto Zimmermann are identical in size to the original discs. Other manufacturers often dimension the ventilation channel slightly wider in order to save material - at the expense of braking quality, as this makes the braking surfaces thinner. The disc therefore wears faster and is less thermally resilient.

Not only the width of the ventilation channel but also its design is a quality feature. At Otto Zimmermann GmbH, this is designed as closely as possible to the original part, as the design of the ventilation channel not only defines the heat dissipation, but also the stability of the disc.

So if the original part has straight, angled or curved ribs, the Zimmermann brake disc is designed in exactly the same way. If the original disc was constructed with pillars in the ventilation duct, the same design is used here too. This ensures maximum quality and safety by following the specifications of the original parts.

Many of Otto Zimmermann's customers are impressed during a visit to the factory by how conscientiously the quality promises are implemented and the high level of tolerance adherence in production: Every worker in the Zimmermann production is sensitized to detecting material defects. During the production process, for example, the discs are randomly checked for running properties such as uneven thickness, axial run-out and flatness of the functional surface. This is the only way to guarantee the highest possible level of safety and braking comfort in the end product.