Manufacturer Otto Zimmermann attaches great importance to quality and customer satisfaction when developing and manufacturing their spare parts for the automotive aftermarket. This is why the company is in regular contact with independent garages and obtains feedback and suggestions directly from the field.

For independent garages, quality is a decisive factor in addition to price when it comes to spare parts. Particularly when it comes to safety-relevant parts such as brakes, a cost-effective alternative must not be at the expense of performance. Otto Zimmermann supplies the aftermarket with brake discs that offer the same quality as the car manufacturer's original brake discs, such as the Steelhub Compound Brake Discs. Through dialog with workshop operators, the manufacturer gains insight into the needs of practitioners in order to be able to offer the best possible solutions for the requirements of independent workshops.

Steel hub compound brake discs in original equipment quality

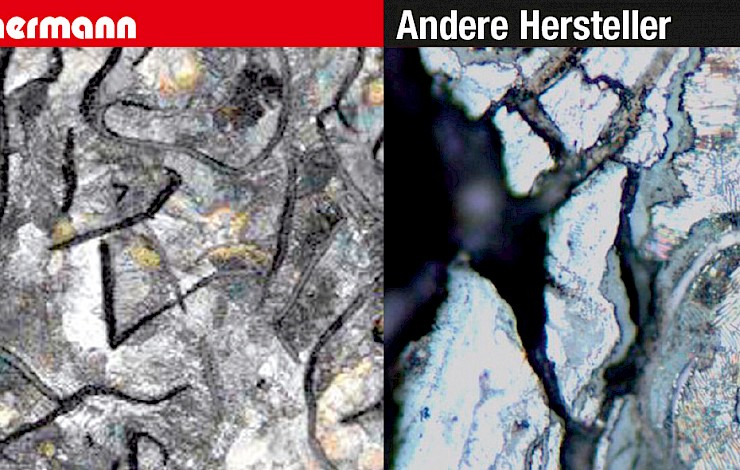

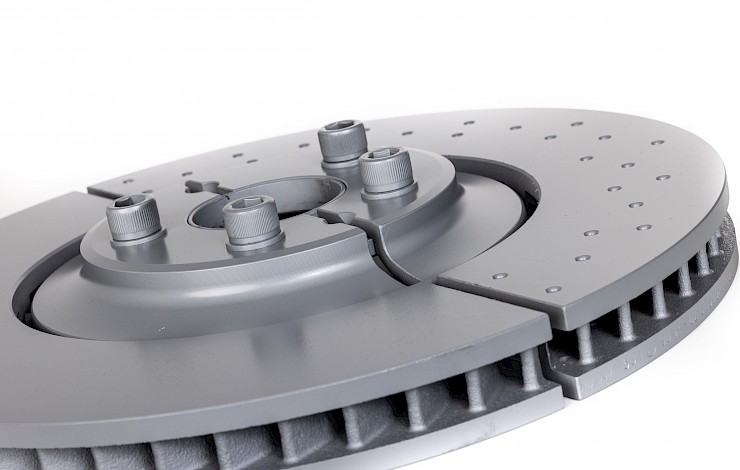

One example of the many discussions with workshops is the current video interview with Otto Zimmermann, which is about the Formula:S brake disc. Formula:S is a compound brake disc consisting of a steel hub and a gray cast iron friction ring, as used by car manufacturer Mercedes Benz, for example. In the interview, mechatronics engineer Simon Stapf, who works in a workshop that specializes in Mercedes Benz vehicles, explains that the Formula:S brake disc from Otto Zimmermann is in no way inferior to the original Mercedes Benz brake disc in terms of quality. One of the quality features cited is the design of the brake disc's ventilation channel, which is in line with the manufacturer's specifications. This guarantees optimized ventilation and even cooling of the brake disc.

Solution-oriented and cost-effective

When fitting steel hub brake discs, both original brake discs and Formula:S brake discs, there are a few things for workshops to bear in mind: For example, the wheel hub must not be deformed by rough hammer blows during disassembly. A wheel hub that is no longer even leads to vibration and uneven wear of the brake discs. Further measures for safe handling can be found in the pictograms. To make safe installation easier for workshops, Otto Zimmermann offers a suitable spacer ring that makes it possible to measure the axial run-out, which is not possible with a standard measuring device. This prevents complaints and enables workshops to offer their customers cost-effective, high-quality spare parts that meet all requirements.

You can watch the full interview here: https://www.youtube.com/watch?v=k5kgea27GJw