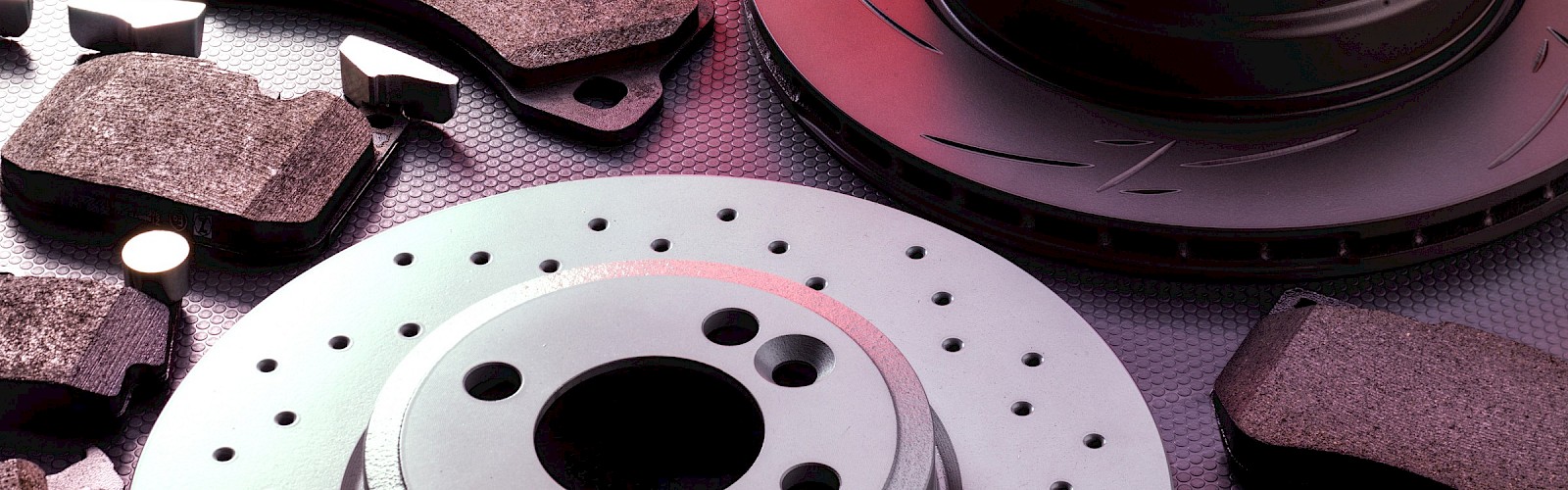

For many decades, Otto Zimmermann has been developing and manufacturing brake discs and its own brake pads, precisely engineered to work in tandem. The result: an optimized friction pairing that delivers maximum safety, consistent performance, and exceptional comfort – both in everyday driving and under extreme conditions.

Coordinated system for consistent braking performance

The best braking effect is achieved when all components interact optimally. Friction coefficient, lubrication, and wear influence this interaction. During braking, particles from both the brake disc and pad are worn away and combine to form what is known as a third layer – also referred to as the “Third Body Layer.”

The composition and stability of this layer significantly affect the friction coefficient and, in turn, the braking behavior. That’s why it is especially important that brake discs and corresponding pads are engineered to match during development and are manufactured and supplied by the same company.

The interaction between Zimmermann brake pads and brake discs ensures a consistently high friction coefficient, short stopping distances, and enhanced driving comfort. Even under thermal stress – such as prolonged downhill driving or dynamic performance – the braking power remains stable and dependable.

Advantages of coordinated friction materials

Zimmermann brake pads are developed with precision to complement the material properties of Zimmermann brake discs. The targeted material mixtures not only ensure excellent braking performance, but also reduced wear and minimal particle abrasion. The result: extended service life for both pads and discs – delivering clear advantages in cost-efficiency and environmental sustainability.

At the same time, friction materials also contribute to a quieter, smoother braking experience. In addition, noise and vibration reduction during braking leads to a more comfortable driving experience.

Safety through standards and a plus in motorsport

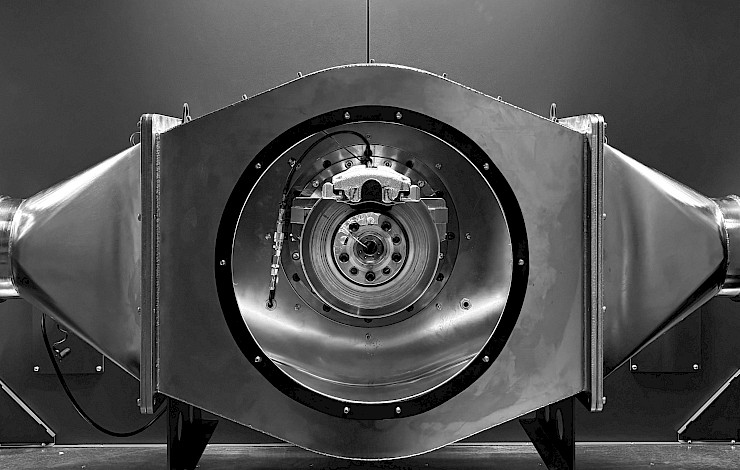

All Zimmermann brake components are tested and approved in accordance with the ECE R90 standard. Furthermore, additional tests are conducted on the company's own brake test benches and under real-world extreme conditions in motorsport. Otto Zimmermann thereby ensures that the combination of brake discs and pads not only meets legal requirements, but also sets the highest standards in terms of safety and performance.

With its systematic approach to developing brake discs and brake pads as a perfectly matched unit, Otto Zimmermann reinforces its commitment to bringing vehicles to a safe and reliable stop – both in everyday traffic and on the racetrack. Naturally, the OE quality of each individual brake component remains a key priority.