Guaranteed quality – and safe!

Permanent controls in all phases of manufacturing guarantee consistent quality. Friction coefficient stability, compressibility, shearing strength and pad stability are continually monitored in the laboratory. As a rule our brake pads are pre-treated in a so-called "scorching" process, in order to guarantee optimal brake performance from day one (even before initially engaging the brake pads and discs.)

Friction coefficient

During the friction coefficient testing, an average friction coefficient at various temperatures is determined. The measurement is performed before, during and after the temperature load. The aim is to maintain a relatively constant friction coefficient. For example has to be avoided, that there is a high reduction of the friction coefficient because of increasing temperature (known as brake fade).

Wear

During each friction coefficient testing the wear is also documented.

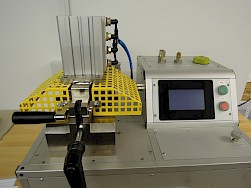

Compressibility test

During the compressibility test it is checked how far the friction material can be compressed at different temperatures. If the friction material can be compressed too much as of certain temperatures the desired braking effect cannot be achieved anymore.

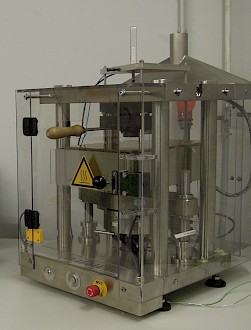

Shearing strength

The friction material and the backing plate are bonded together under high pressure. In addition, for some pads pins are incorporated into backing plate to prevent the detachment of the friction material from the backing plate. Intention of the shearing strength tests the is to determine the force, under which the friction material detach from the backing plate.